Cold Forming Alu Foil in Drug Packaging: A Superior Choice for Safe & Effective Medicine Delivery

Advantages of Cold Forming Alu Foil in Drug Packaging

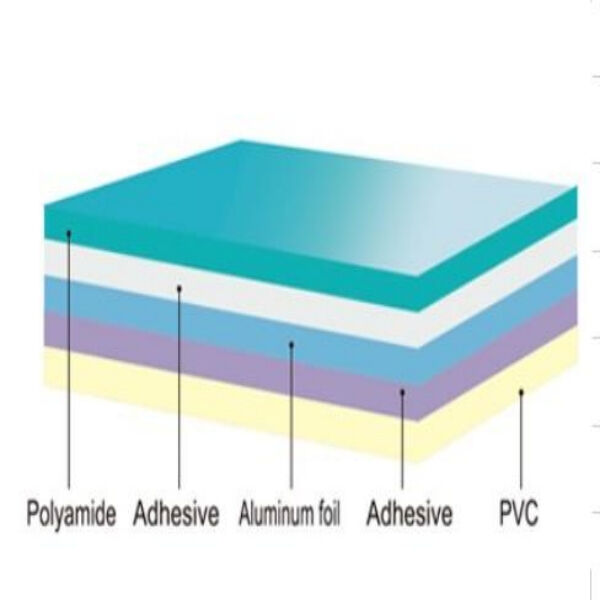

Cold Forming aluminum (alu) foil is a favorite choice the pharmaceutical industry for packaging items. There are many advantages to using Cold Forming Alu Foil in Drug Packaging. A number of its most crucial advantages incorporate being tamper-resistant, offering excellent barrier against temperature, dampness, and air, and being in a position to shape as much as a specific design, form, and size. Moreover, Hanlin Pharmaceutical Packaging it would likely also withstand high processing and protect item integrity while supplying a medicine delivery safe system.

Innovation in Cold Forming Alu Foil in Drug Packaging

The pharmaceutical industry has to stick to strict laws regarding medicine packaging. This is why there is the requirement for revolutionary drug packaging methods. The development of Cold Forming Alu for drug packaging is an innovation. It is an effective way make sure foil wrapping critical pharmaceutical goods the end-users in perfect condition.

Safety of Cold Forming Alu Foil in Drug Packaging

Cold Forming Alu is named safe as of the Food and Drug Administration (FDA) and is compliant with Current Good Manufacturing Practice (CGMP) laws. It undergoes significant testing ensure it satisfies the necessary standards to be utilized in medicine packaging.

Uses of Cold Forming Alu Foil in Drug Packaging

Cold Forming Alu is best known for the use within blister packaging for solid dosage forms. The wrapping foil paper packaging helps to ensure that the medication stays free of contamination, protect effectiveness, and is effortless to utilize. The pouches which are tight-seal counter moisture and air from stepping to the medication. Continuous development of cold forming aluminum is rendering it more worthy of an easy array of products, from tablets, capsules, and pills to suppositories, ampoules, and syringes.

How to Use Cold Forming Alu Foil in Drug Packaging

Cold Forming Alu works best whenever operate through a specialized machine stretches and forms it to the desired shape and then heat-seals it shut. The drug, when you look at the total correct amount is deposited into the formed packaging, and the final blister pack is sealed by pressing the alu foil and a plastic backing together.

Services and Quality of Cold Forming Alu Foil in Drug Packaging

Through its whole lifespan, Cold Forming Alu for drug packaging produces unmatched efficiency and service. It keeps the quality regarding the medicine by providing complete protection impeccable barrier and sealing properties. Additionally, it is furthermore an eco-friendly solution maybe it's easily recycled.

Applications of Cold Forming Alu Foil in Drug Packaging:

Cold Forming Alu used in drug packaging has its own application in the pharmaceutical industry. Its primary utilize is the packaging of solid-dosage medicines, alu foil packaging including capsules, tablets, powders, and effervescent. It is also employed in the packaging of medical devices such as syringes and ampoules. Given that properties evolve, it is becoming well suited for fluids, inhalants, and more delicate drug that requires protection and security.

Table of Contents

- Advantages of Cold Forming Alu Foil in Drug Packaging

- Innovation in Cold Forming Alu Foil in Drug Packaging

- Safety of Cold Forming Alu Foil in Drug Packaging

- Uses of Cold Forming Alu Foil in Drug Packaging

- How to Use Cold Forming Alu Foil in Drug Packaging

- Services and Quality of Cold Forming Alu Foil in Drug Packaging

- Applications of Cold Forming Alu Foil in Drug Packaging:

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS

KK

KK

UZ

UZ